Key Takeaways

- Understand the specific requirements of your pipeline to choose a suitable caliper.

- Evaluate the features and capabilities of available rental calipers.

- Consider the benefits of renting over purchasing, especially for short-term projects.

- Ensure proper calibration and maintenance of the caliper for accurate measurements.

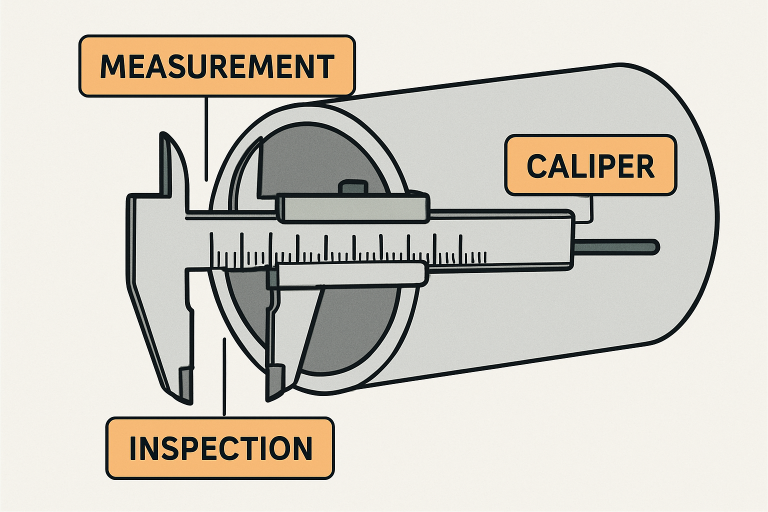

Ensuring the integrity and safety of pipelines is a top priority for operators across industries. The success of a pipeline inspection program hinges not just on frequency and timing, but also on the precision and reliability of the inspection tools selected. For many inspection teams, a rental pipeline caliper tool for integrity assessments offers an attractive solution, striking a balance between cost and performance while delivering accurate results crucial for ongoing pipeline safety.

Selecting the right rental caliper for pipeline inspections requires careful evaluation of both the pipeline conditions and the caliper’s specifications. It is crucial to ensure that the measurement precision and material durability match the specific needs, particularly in environments with corrosive chemicals or high pressures. Renting is ideal for short-term projects, offering access to advanced technology without ownership costs. Rental providers ensure that tools are well-maintained and calibrated for reliability.

Understanding Pipeline Inspection Needs

Before you begin the search for a rental caliper, outline your inspection parameters in detail. Start by identifying the primary objectives—are you screening for ovality and dents, or do you also need to detect wall thickness variations and corrosion? The pipe’s diameter, wall material, length, and expected operating pressures will all shape the selection criteria. Some pipelines may contain bends, valves, or reducers that require a caliper with configurable sensors or higher measurement resolution. Inspection teams should also factor in past anomalies, projected operating conditions, and budgetary constraints. According to the Pipeline and Hazardous Materials Safety Administration (PHMSA), leveraging the right inspection tools is foundational for optimizing preventive maintenance and ensuring pipeline longevity.

Additionally, choosing a caliper with flexible reporting and data integration capabilities can streamline post-inspection analysis. Teams should also consider the availability of technical support and calibration services from the rental provider to ensure accurate results. Finally, understanding the deployment logistics, including pig launcher and receiver compatibility, can prevent costly delays during inspection operations.

Evaluating Rental Caliper Features

Not all pipeline calipers are built alike. The features most relevant to your inspection goals may include:

- Measurement Accuracy: Seek a caliper with a measurement tolerance that meets or exceeds industry standards for the expected defect types. Higher precision is essential for pipelines operating under critical conditions.

- Durability: Look for calipers constructed from corrosion-resistant alloys or reinforced polymers, as these materials will withstand suboptimal inspection environments and prolong the tool’s lifespan.

- Data Recording: Digital recording and wireless data transfer capabilities are becoming increasingly standard, allowing for seamless integration with your data management and analysis platforms.

- Compatibility: Ensure the selected caliper accommodates the pipe’s diameter and length and can interface with any proprietary inspection or pig tracking systems already in use.

Inspection efficiency depends on intuitive controls, lightweight construction for portability, and the ability to retrieve caliper data easily after inspection. Ask rental providers about available accessories, such as specialized brushes or interchangeable sensor heads, that may further enhance your inspection scope.

Benefits of Renting Over Purchasing

Renting a pipeline caliper is a practical choice for many project-oriented or maintenance-driven inspection scenarios. Here’s why renting is often preferable:

- Cost-Effectiveness: Rentals eliminate upfront expenditure and ongoing maintenance costs, making inspections more predictable and budget-friendly for pipeline operators.

- Access to Advanced Equipment: Reputable rental services keep their fleets up to date with the latest sensor technology, so you’re more likely to use cutting-edge tools than if purchasing outright.

- Maintenance and Calibration: Rental calipers are routinely serviced to meet safety and performance regulations, reducing the risk of error due to equipment drift or lack of calibration. This can save inspection crews both time and money while minimizing risk.

As the pipeline industry faces increasing regulatory scrutiny, the use of calibrated and certified inspection equipment is more vital than ever. The Pipeline and Hazardous Materials Safety Administration (PHMSA) continuously updates guidelines for tool calibration to enforce best practices nationwide.

Ensuring Proper Calibration and Maintenance

Reliable inspection data starts with a well-maintained caliper. Most rental providers offer detailed maintenance records and calibration certificates for their equipment. Before your inspection, request these records and visually inspect the caliper for signs of wear. During field operations, follow the recommended handling and cleaning protocols to prevent introducing errors or contaminants that could compromise measurement accuracy.

Schedule periodic recalibrations for long or phased inspection projects, as well as thorough post-use cleaning, to prevent sensor degradation. A proactive approach to care ensures your rental caliper consistently delivers precise, actionable results and meets compliance standards.

Conclusion

Selecting the appropriate rental caliper for pipeline inspection programs is a nuanced process shaped by pipeline-specific requirements, environmental considerations, and inspection objectives. Careful evaluation of caliper capabilities—including measurement accuracy, durability, data logging, and compatibility—combined with the operational and financial benefits of renting, enables operators to achieve timely, dependable integrity assessments. Diligence in calibration and maintenance ensures measurement accuracy, preserving pipeline safety and performance over time.